Unlocking the design freedom: The development of a gyroscopic cup holder

Published: 12.06.2025 / Publication / Mechanical and product design / Blog

A novel gyroscopic cup holder is designed and developed using a 3D printing technology. The gyroscopic cup holder provides a stability for the cups, thus avoids possible spillage. The critical component of the mounting system is analysed to understand the influences of 3D the printing parameters.

Abstract

Whether riding on a bike or taking business flights across continents, people often want to sip from their bottles or cups. However, the bumpy roads and turbulence make it difficult to place the cups stable. To address the challenge, a novel gyroscopic cup holder is designed and developed using a 3D technology. The gyroscopic cup holder provides a stability for the cups, thus avoids possible spillage.

Introduction

Each day, millions travel across the world using different means of transportation. Whether riding on a bike to clear the mind, or taking flights on business trips across continents, people often want to sip from their bottles, cups or cans. However, the bumpy roads, the waves at the sea, or the air turbulence make it difficult to place the cups stable. To address the challenge, a novel gyroscopic cup holder is designed and prototyped using a fused filament fabrication (FFF) method. The Ender 3-pro 3D printer is used to develop the functional prototype from the polyethylene terephthalate glycol (PETG) filament. The development of the gyroscopic system is followed by a design of experiment (DoE) analysis to investigate the influences of the 3D printing parameters on the dimensional accuracy of the critical component.

Methods

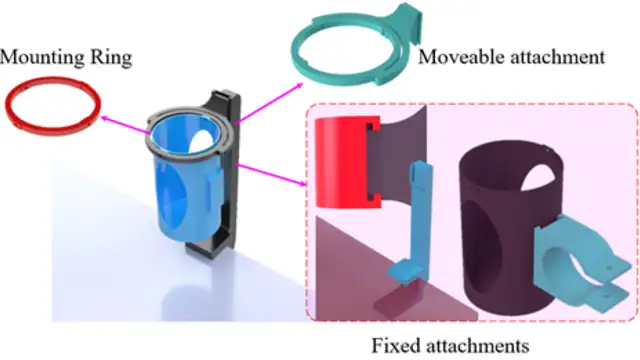

The design process follows the conventional product development steps (Ashby, 2017; Mattson & Sorensen, 2020) and aims to lower the centre of mass of the system. The gyroscopic system consists of a mounting ring, a moveable, and a fixed attachment. Altogether, the assembled sub-components provide the cup freedom of rotations in X-Z and Y-Z planes, thus make sure the content in cup is not spilled. The 3D CAD rendering that shows the components and their assembly is presented in Fig.1.

The prototypes of the system and the cup were manufactured using additive manufacturing technology. Fig. 2 shows the assembled prototype of the design presented in Fig.1. We used typical 3D printing parameters to produce the cup, the movable and the fixed attachment sub-components. The customised cup contains 330 ml of drinks (hot or cold beverages), which is a standard volume.

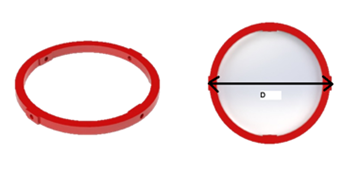

The mounting ring gives the cup a rotational degree of freedom in X-Z plane. In addition, it connects the cup with the moveable attachment. This makes the ring a critical component of the system. Manufacturing a dimensionally stable mounting ring is crucial for the system assembly and operation. Fig. 3 presents the critical dimension of the mounting ring.

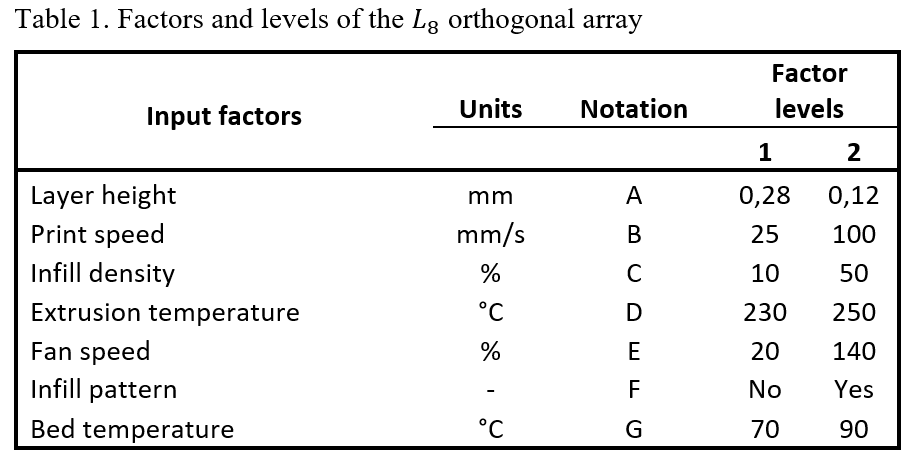

The internal diameter D with a nominal value of 86 mm is the critical dimension of the component. Manufacturing the component with accurate diameter is a requirement, however in 3D printing, the process parameters strongly influence the dimensional accuracy of additive-manufactured parts. To understand the influence of the process parameters, and to determine the optimum settings that lead to a dimensionally accurate mounting ring, we used the Taguchi DoE (Yang & El-Haik, 2003). The Taguchi method systematically tests several variables at once using fractional factorial DoE (Ross, 1996). The fractional factorial experiment is based on first, selecting appropriate orthogonal array for the analysis, and second, conducting statistical analyses using mean of responses and analysis of variance (ANOVA) methods (Yang & El-Haik, 2003). We studied the influences of seven 3D printing parameters (factors) at two different levels using the L8 orthogonal array. The details of the factors and levels are presented in Table 1.

Results and discussion

The DoE should have two test replicates; hence we produced two samples for each experimental run. Fig. 4 shows the 3D printed mounting rings.

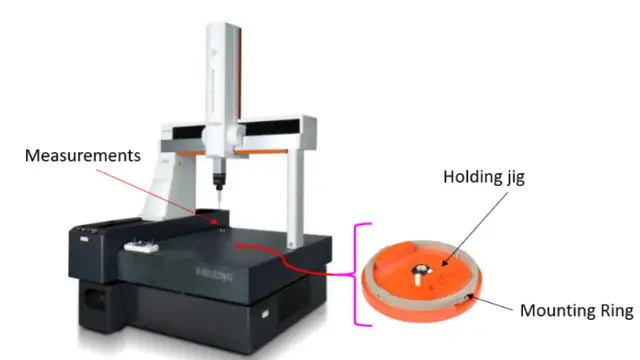

To conduct the measurements, we used the Crysta-Apex from Mitutoyo, a high accuracy coordinate measuring machine (CMM). We used custom made jig to fix the mounting ring on the CMM, see Fig.5. A 4 mm diameter probe is used for the measurements.

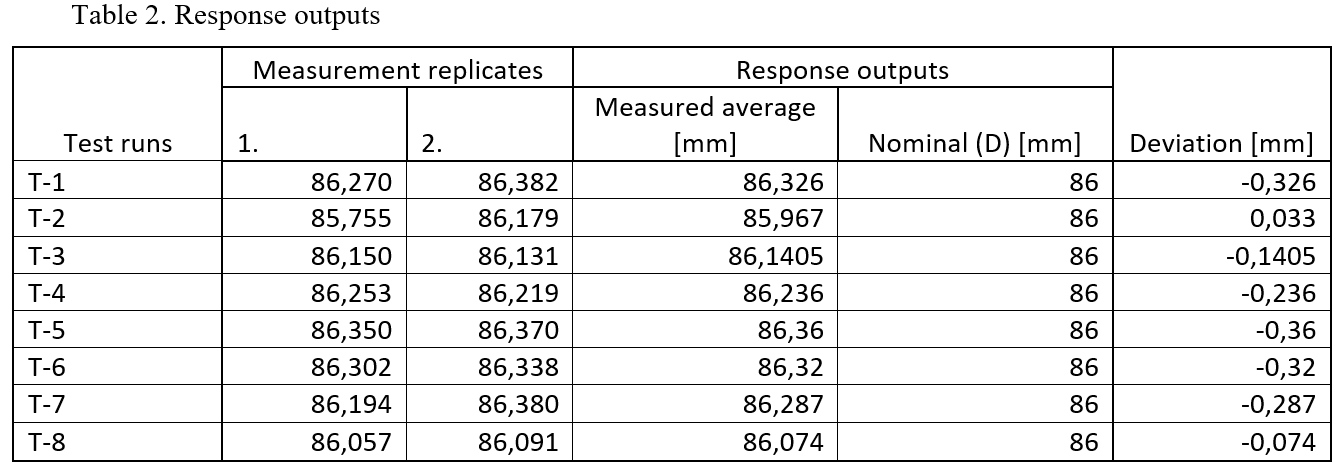

The summary of the measurement results is present Table 2.

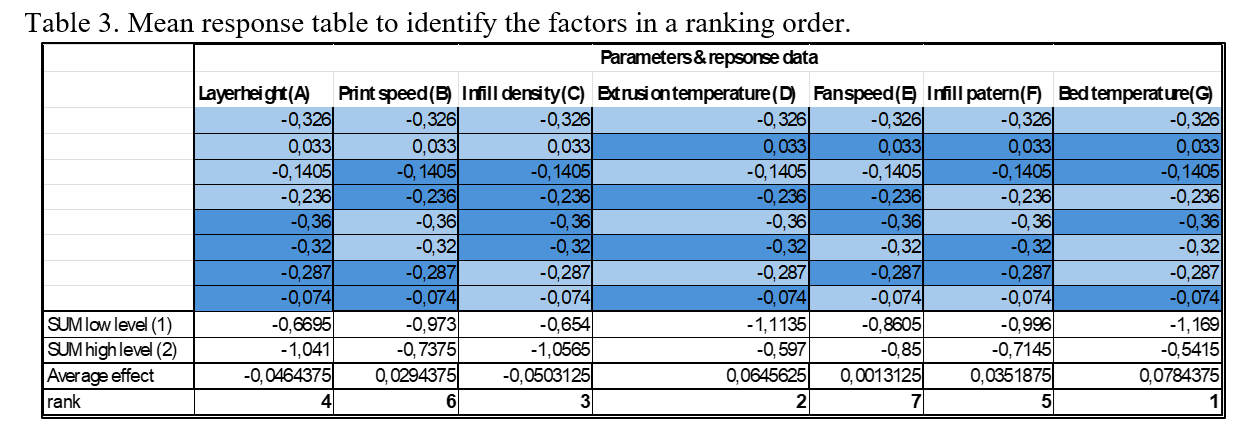

The mean responses analysis identifies influences of the factors on the quality characteristics (internal diameter of the mounting ring) in a ranking order. Accordingly, the bed temperature, extrusion temperature, and infill density parameters ranked 1st, 2nd, and 3rd. While the layer height, infill pattern, print speed and fan speed ranked between 4th and 7th in a respective order. The summary of the analysis is presented in Table 3.

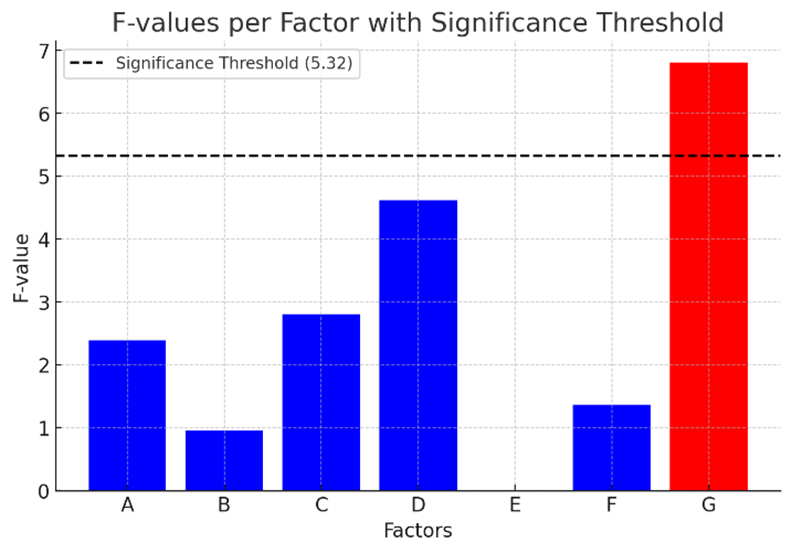

The ANOVA also showed the ranking order of the factors’ influences on the quality characteristic, however only identified the bed temperature as a statistically significant factor with F-value = 6.81for a critical F-value of F (5%,1,8) = 5.32. The ANOVA is used to identify the F-values of each factor, see Fig. 6.

To identify the optimum settings that lead to a good quality characteristic, the responses of factors’ levels that have minimum deviations from the nominal values are considered. Accordingly, the optimum settings for a good quality are A1 B2 C1 D2 E2 F2 G2. This means, a dimensionally accurate mounting ring is obtained when the layer height is 0.28 mm, print speed is 100 mm/s, infill density is 10%, extrusion temperature is 250℃, the fan speed is140%, no infill patter is used, and the print bed temperature is 90℃.

The prediction of the optimum response μ is made by considering the mean responses of the first three influential factors (G, D, C) in the ranking order. The optimum response is predicted as (Yang & El-Haik, 2003),

In Eq. (1), G2 D2 C1 are the factors’ levels that lead to minimum deviations, is the mean of the total responses. Based on the analysis, the mean response becomes,

A gyroscopic cup-holder was successfully designed, 3D printed and tested showcasing innovative development processes indicated in this work. The cup-holder's design integrates interchangeable attachments and mechanisms to address the challenge of keeping drinks steady in dynamic environments such as boats, bicycles, and planes.

Conclusion

A simplified gyroscopic mounting system for cups is designed and prototyped using 3D printing technology. The study identifies the mounting ring of the gyroscopic system as a critical component; hence, a statistical analysis was made to understand the influences of 3D printing parameters on the accuracy of the inner diameter of the ring. Fractional DoE using the Taguchi method was used to investigate the influences of seven parameters on the dimensional stability. The mean response output showed that the bed temperature, extrusion temperature, and infill density parameters were the first three influential factors in a ranking order, while ANOVA identified the print bed temperature as the only statistically significant factor for the studied quality characteristics. This DoE analysis is crucial, and it can be used as a basis for a multi-level factorial design to investigate the correlation between process parameter and quality characteristics further.

Author: Ricardo Gielen, student

Co-author: Silas Gebrehiwot, Senior Lecturer in Mechanical Engineering

References

Ashby M. F. (2011). The Design Process. In Materials Selection in Mechanical Design (4th ed., pp. 15-29). Butterworth-Heinemann.https://doi.org/10.1016/B978-1-85617-663-7.00002-3 .

Mattson C. A., & Sorensen C. D. (2020). Product Development Principles and Tools for Creating Desirable and Transferable Designs. https://doi.org/10.1007/978-3-030-14899-7 .

Ross, P.J. (1996) Taguchi Techniques for Quality Engineering: Loss Function, Orthogonal Experiments, Parameter and Tolerance Design (2nd ed). McGraw-Hill, New York.

Yang K., & El-Haik B. S. (2003). Design for Six Sigma: A Roadmap for Product Development (2nd ed). The McGraw-Hill Companies, Inc.