Designing and 3D printing a bow thruster propeller

Published: 18.12.2025 / Blog

This blog post is by Wilhelm Guarnieri and Robin Calander, students on the Process- och materialteknik programme at Arcada. It follows the journey from a simple idea to a 3D-printed bow thruster tested at sea, showcasing modern design, hands-on engineering, and the challenges of using polymers in marine environments.

From concept to creation

What started as a simple idea — improving the bow thruster of an old boat from the 1980’s — quickly turned into a large-scale project for us. The original propeller was outdated and underpowered. Could a modern and more efficient version be 3D printed from a polymer (PETG) and still be durable and reliable?

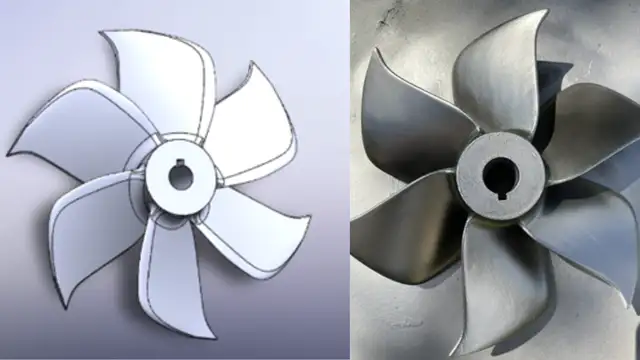

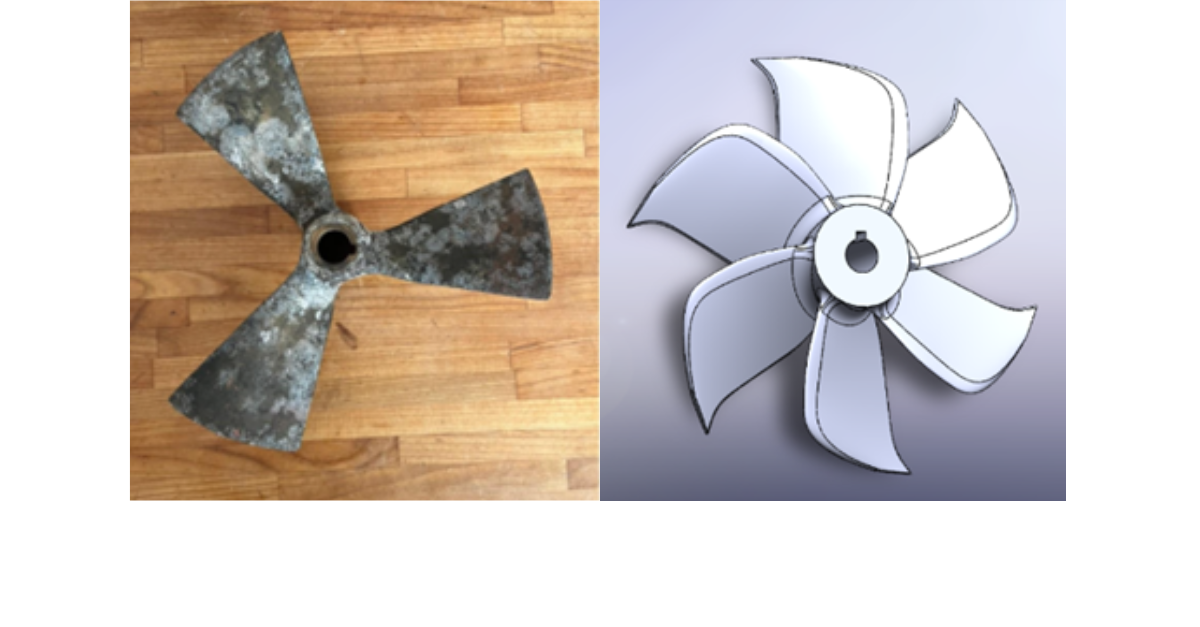

The goal of the project was to design the bow thruster propeller better and manufacture it using fused filament manufacturing (FFF) 3D printing. The Fig. 1 shows the current outdated bow thruster and the modified version of its design using the SolidWorks CAD tool.

Designing the propeller

Using the SolidWorks, we designed multiple prototypes, refining each version based on the recent research that focus on the state-of-the-art in bow thrust propeller design. We compared ideas in design, such as controllable pitch (CPP) where the blade angle can be altered by the operator, and a fixed pitch (FPP) where the blade angle is fixed but applicable for the simpler FPP model due to compatibility concerns. This made the 3D printing a feasible manufacturing method.

The final design has features including a six propeller blades instead of a three, thus reducing vibration and cavitation, all the while improving thrust. This design achieved the goal implied on obtaining a more efficient yet simple and durable propeller design.

This project reflects Arcada’s hands-on educating spirit — combining theory with real-world manufacturing and design.

The 3D printing process

We began printing our designs using the carbon fibre-reinforced PLA, but quickly discovered some drawbacks on the material. Although the material is strong, it was difficult to print due to the limitation of the 3D printer capability. After multiple setbacks with printing failures, we switched material to PETG (Polyethylene Terephthalate Glycol-modified).

After the switch of material, we quickly got a final product printed successfully, and test-fitted it to the boat. Confirming our tolerances on the fitting, it was passed on to surface treatment and testing.

Treating the propeller

Some of the common problems with application of structures in seawater are corrosion and barnacle growth. To help the material with saltwater degradation and to prevent barnacles from growing, the propeller was carefully sanded and painted with plastic paint. This achieved a smooth finish, protecting the PETG underneath and making the propeller more hydrophobic.

Testing of the propeller

Throughout the summer, the propeller was tested extensively in a real-world boat driving. During the four months of the application, the bow thrust propeller performed well, and by comparison, it provided:

- ~25% increase in thrust

- No cavitation issues

- Improved manoeuvrability when docking against wind and waves

However, at the end of the season, barnacles started to grow despite our measures to prevent it. This is a reminder that applications in seawater are still complicated, and marine growth is still a concern. However, the problem could be solved using anti-fouling paint. When removing the propeller for inspection, one of the propeller blades cracked. This also shows that the regular plastic paint does not provide adequate protection against saltwater, as the crack is most certainly emanated from the saltwater degrading the material. These generally are valuable lessons in the future bow thrust propeller design.

Outcome of the project

Despite setbacks, the project was a success. It was proved that 3D printing in PETG can be utilized in the manufacture of marine components, as long as the design, material, and final treatment are all made in accordance with the application sought. Using the knowledge gained from this project, all the issues could easily be fixed in a new revision of the design, most notably paying more attention to the treatment of the propeller using proper types of paint.

Final thoughts

In our opinion, this project reflects Arcada’s hands-on educating spirit — combining theory with real-world manufacturing and design. We took an idea—and made it a reality. This proves the importance of knowledge in both theoretical as well as practical knowledge. This is why we like Arcada’s way of teaching the future generations of engineers.

Authors: Wilhelm Guarnieri and Robin Calander, students on the Process- och materialteknik programme at Arcada.